Description

The L36-150 TC-CE model is a semi-automatic flexographic printing press for the 3-colour printing of adhesive tape, the tape cutting and rewinding in preset widths and lengths. Working cycle: the machine unwinds, Corona treats, prints, cuts and rewinds the tape; it slows down and turns automatically the rewind turrets when the preset length is reached.

Capable to print: PVC, OPP, ADHESIVE PAPER (Pre-Treated, Solvent, Hot-Melt, Acrylic Water & Solvent Basis) and gummed paper.

With an optional device, the machine can also print not adhesive material (not adhesive paper, not adhesive OPP, aluminum and reinforced paper).

Advantages

- 3 printing stations with quick adjustment.

- Exhausting suction system.

- Felt roller to clean the back side of tape.

- Pneumatic pumps for primer and release.

- Primer and release stations.

Key Features

- 3 colors.

- 3″ mechanical unwind mandrel with dry clutch.

- Tefloned central impression drum (standard) or ceramic central impression drum (on demand).

- Width and length roll 150 mm – max. diameter 420 mm.

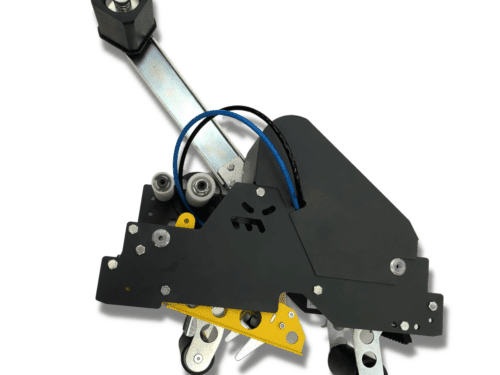

- Slitting device by razor blades.

- Set of spacers for slitting blade holders setting: 12 mm – 15 mm – 19 mm – 25 mm – 30 mm – 38 mm.

- Corona treatment.

- 3 hot air drying tunnels with electric resistors.

- Speed control and adjustment from 0 to 160 m/min by inverter.

- Anti-accident protection preset for the exhaustion of solvents.

- Ventilation system (3 motor fans).

- Exhaust system (5 suction fans).

- Printed tape rewinding on change-over turrets.

- Primer station.

- Release station.

Options

- ACL50 to print on the adhesive side of transparent tape.

- Coating station to apply primer and release coats.

- Peristaltic pumps for ink trays for the automatic feeding of the ink.

- Pneumatic unwind roller.

- Machine available without Corona Treatment.

- Slitting device with pneumatic score knives for cutting reinforced tape, filament tape or masking tape.

Files

L36-150 TC-CE Datasheet