Description

FoodPack Energy is aimed at companies that wish to increase their packaging capabilities. It features a reinforced sealing roller and a larger sealing area compared to entry-level models, making it suitable for more demanding packaging tasks. The Roto Energy version further enhances productivity with its rotary table design. The machine supports various packaging applications including sealing, MAP/ATP, vacuum and leather packaging.

Its ultra-compact design ensures it is easy to fit into confined spaces, making it ideal for businesses with limited space but who need advanced packaging solutions. This version enhances production efficiency by allowing simultaneous loading/unloading and sealing/cutting operations at different stations.

Sealing

MAP/ATP

Vacuum

Sealing up to 17cpm

Reinforced sealing roller

The enlarged sealing roller provides greater sealing force, making it suitable for more robust and demanding packaging applications. This feature ensures a stronger seal, which is vital to maintaining the integrity and quality of packaged products, particularly in MAP and vacuum packaging.

Large sealing area

The increased sealing area allows for the packaging of larger or multiple items at the same time, enhancing the machine's flexibility and productivity.This feature is particularly beneficial for companies looking to increase their packaging production without compromising on quality.

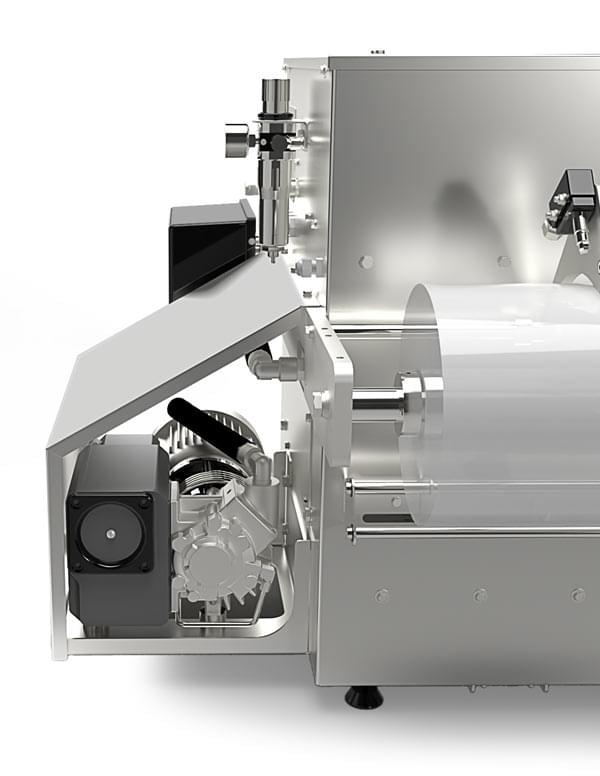

Extremely compact design

Despite its advanced capabilities, FoodPack Energy maintains a compact footprint. All components, including the motor, are enclosed in a space-saving chassis, making it an efficient choice for workplaces with limited space.

Automatic unwinding and rewinding

This system automates the film handling process, ensuring accurate positioning of the heat sealing film and efficient rewinding of the residues after sealing. The optional "centering print" system is ideal for operations that require precise alignment of the printed film with the tray, enhancing the aesthetics of the packaged product.

Technical Specifications

- Dimensions: 103 x 93 x h 66 cm.

- Weight: 95 (N) - 110 (VG) Kg.

- Air consumption : 6 bar - 7 Nlt/cycle.

- Sealing area: 1.5 lt: 400 x 270 x h 145 mm.

Technology

- PROGAS System

Technology patented by ILPRA that guarantees lower gas use and higher working speed. Available on all models of this series.

Product Gallery