Description

FoodPack Basic is an ideal solution for companies starting out with tray sealing or with smaller production volumes. Its compact design allows for easy placement in confined spaces while offering a range of packaging options including sealing, MAP/ATP and vacuum. The Roto Basic version enhances productivity by allowing simultaneous loading/unloading and sealing/cutting operations. The E-Mec version further increases the machine's efficiency with its electromechanical drive. The touch screen panel simplifies operation and allows multiple recipes to be stored, facilitating quick changes between different packaging needs.

Suitable for packaging a variety of foodstuffs such as pasta, meat, fish and ready meals, FoodPack Basic is also available in a Roto Basic version with rotary table and an E-Mec version.

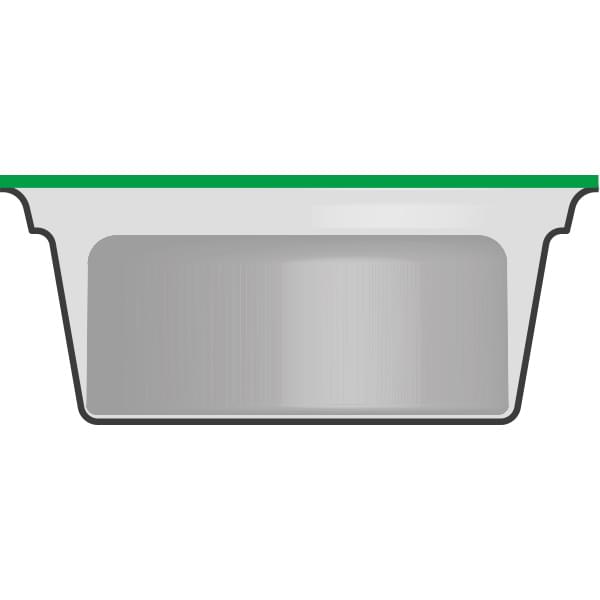

Sealing

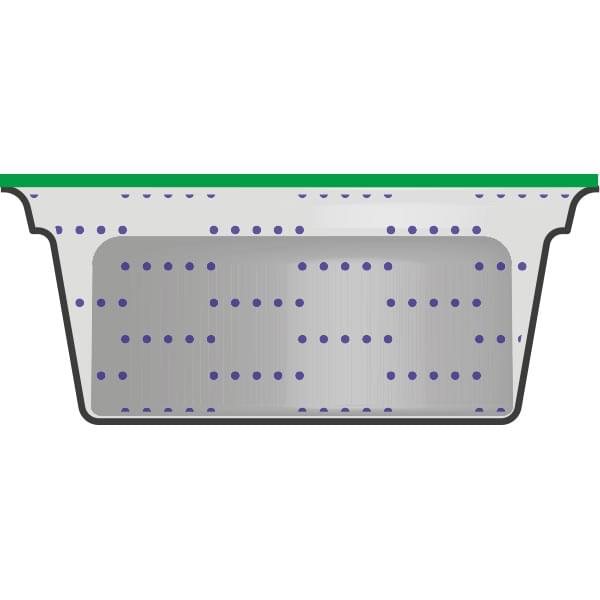

MAP/ATP

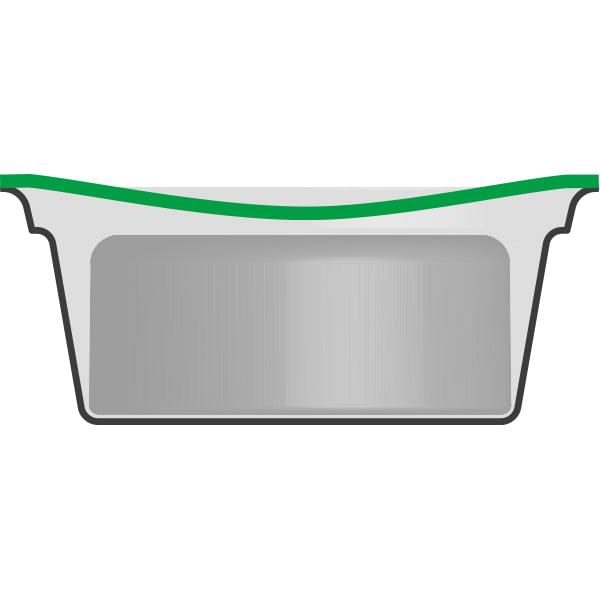

Vacuum

Sealing up to 17cpm

Touch screen panel

This panel simplifies operation by allowing easy setting of all working parameters. It also allows multiple recipes to be stored for quick and efficient changes, making the machine highly adaptable to different packaging needs. The intuitive interface ensures that operators can manage the machine with minimal training, boosting overall productivity.

Quick mould change

The design of FoodPack Basic allows for quick and tool-free mould changes, significantly reducing production downtime. This feature is particularly beneficial for companies that need to frequently switch between different product sizes, giving them the flexibility to quickly and efficiently adapt to different packaging requirements.

Electronic winder & unwinder

This system efficiently manages the film, automatically unwinding the correct amount under the sealing area and rewinding the residue after sealing. The optional 'centering print' system is ideal for precision packaging, especially when using printed films, ensuring that the appearance of the packaging is consistent and professional. This feature is vital to maintaining high standards of packaging quality and aesthetics.

Extremely compact design

The FoodPack Basic's compact frame, which encloses all the machine's components, is designed to save space, making it ideal for businesses with limited working space.Despite its small size, the machine does not compromise on functionality, offering a full range of packaging possibilities in a convenient size.

Technical Specifications

- Dimensions: 91 x 88 x h 63 cm (N) - 104 x 88 x h 63 cm (VG).

- Weight: about 110 (N) - 130 (VG) Kg.

- Air consumption : 6 bar - 5 Nlt/cycle.

- Sealing area : 380 x 270 x h 135 mm.

Technology

- PROGAS System

The ProGas system is a patented technology developed by ILPRA and designed to improve the efficiency and speed of the packaging process. This innovative system works by optimising the use of gas in packaging, ensuring that smaller quantities are used without compromising the quality of the packaging atmosphere. - Optional: E-MEC technology

Based on the fully electromechanical motion of the workstation, this technology allows for higher speed and productivity, offering an efficient solution for companies looking to improve their packaging processes.

Product Gallery