Description

The TTK 5600 automatic packaging machine (5600 - 5600 CS - 5600 MPE - 5600 MPS) is ideal for high capacity applications. They can be used in multiple sectors such as: food, retail, graphics and mailing, mass retail, industrial and textile. These machines can be combined with a heat shrink oven, such as the TT40 & TT40 Twin.

| Models | TTK 5600 | TTK 5600 CS | TTK 5600 MPE | TTK 5600 MPS |

| Maximum product dimensions LxWxH (mm) | 600 x 400 x 160 | 600 x 400 x 240 | 600 x 400 x 240 | Length infinite x 400 x 240 |

| Average packets per hour | 0 – 2400 | 0 – 2400 | 0 – 3600 | 0 – 3600 |

| Types of suitable films | Polyolefin, PVC, polyethylene. | Polyolefin, PVC, polyethylene. | Polyolefin, PVC, OPP, polyethylene. | Polyolefin. |

| Film thickness | 7 to 80 microns. | 7 to 80 microns. | 7 to 80 microns. | 7 to 80 microns. |

| L-shaped sealing bar | Pneumatic supply 5 bar. | Pneumatic supply 5 bar. | Power supply (no pneumatic connection required). | Power supply (no pneumatic connection required). |

| Machine dimensions MxWxD (mm) with closed cover | 2485 x 1245 x 1715 | 2485 x 1245 x 1715 | 2485 x 1245 x 1715 | 2244 x 1795 x 1726 |

| Machine dimensions MxWxD (mm) with open cover | 2485 x 1245 x 1900 | 2485 x 1245 x 1900 | 2485 x 1245 x 1900 | 2244 x 2395 x 1950 |

Advantages

- Very high production, up to 3600 pieces/hour (TTK 5600 MPE & MPS) Control panel with 256 programs.

- User-friendly operation.

- Savings of 70% in labour costs compared to a semi-automatic machine.

Key Features

- Pneumatic supply (60 l/min) (5600 and 5600CS) - Power supply (no pneumatic system connection required) (5600 MPE and 5600 MPS) l/min (5600 & 5600CS).

- Suitable for combination with heat shrink oven such as TT40 & TT40 Twin.

- The speed of the conveyor belt can be adjusted with an inverter.

- Schneider Electric PLC with function control that has 256 programs that can be named and customized.

- Input/output signals allowing the exchange of signals with additional input and output conveyors.

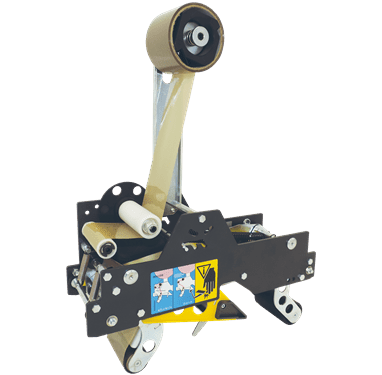

- New film pre-punching kit with adjustable tension.

- Possibility to pack single or multiple packages.

- Control panel with touch screen and USB port (MPE 5600 and 5600 MPS models).

- The opening of the gluing bar, which is adjusted according to the height of the package, can be set on the touch screen control panel (models 5600MPE & 5600MPS).

- Motorised waste film winder controlled by an inverter (models 5600MPE & 5600MPS).

- Illuminated workstation (5600MPE & 5600MPS models).

- Mechanically adjustable welding rod (L) (5600 & 5600 CS) or self-adjusting depending on the height of the product.

- Power supply voltage 230 V 1ph / 2,5 kW.

Options

- Special photocell for printed film.

- Photocell for detecting the end of the film reel.

- Film perforation (models 5600 MPE & 5600 MPS).

- Control pedal (5600 MPE & 5600 MPS models).