Description

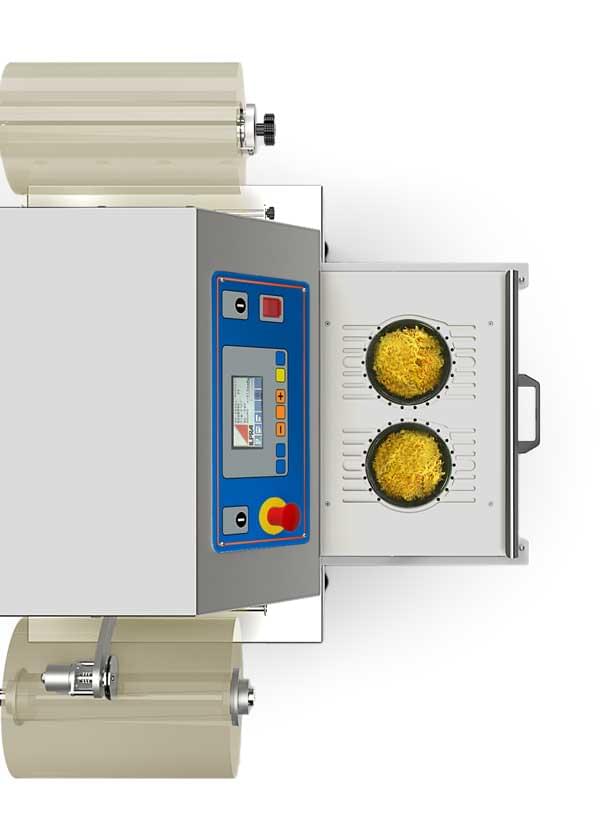

FoodPack 400 is designed for ease of use and packaging flexibility. Its semi-automatic operation, featuring manual tray insertion and ejection, is complemented by an automatic film handling system, making it ideal for a variety of applications.

The machine's large stamping area supports different sizes and types of trays, increasing its versatility. This tray stamping machine is particularly suitable for companies looking for a balance between manual control and automated performance.

Sealing

MAP/ATP

Vacuum

Sealing up to 17cpm

Touch screen panel

The intuitive touchscreen control panel simplifies machine operation, allowing easy configuration and storage of multiple recipes for quick access, improving user experience and operational efficiency.

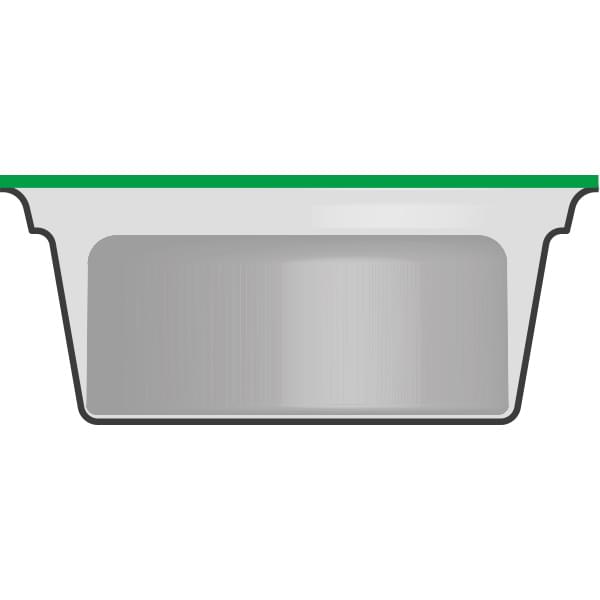

Large sealing area

The large sealing area of the FoodPack 400 increases production volume and allows for flexible mould configurations, making it suitable for a wide range of packaging applications and for adapting to different product sizes.

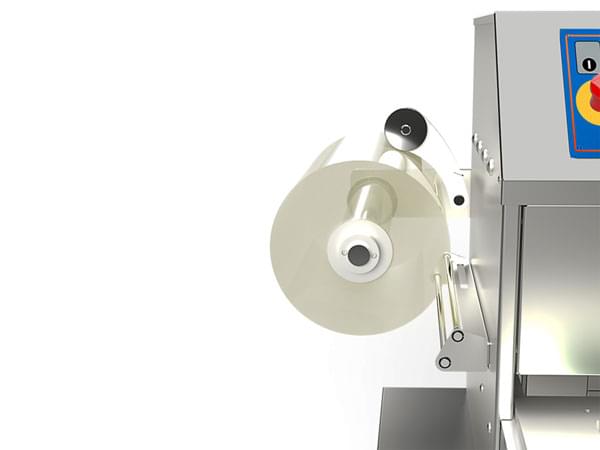

Electronic film management

This function automates film management by accurately unwinding the correct amount of heat-seal film and rewinding the residue after sealing. The system can work with both printed and neutral film and includes an optional "centered print" system for precise alignment of film images.

Quick mould change

Easy removal of moulds facilitates rapid resizing without the need for tools, significantly reducing downtime and increasing productivity.

Technical Specifications

- Dimensions: 106 x 102 x h 143 cm.

- Weight: 160 (N) - 210 (VG) Kg.

- Air consumption: 6 bar - 7 Nlt/cycle.

- Sealing area: 1.5 lt: 400 x 285 x h 135 mm.

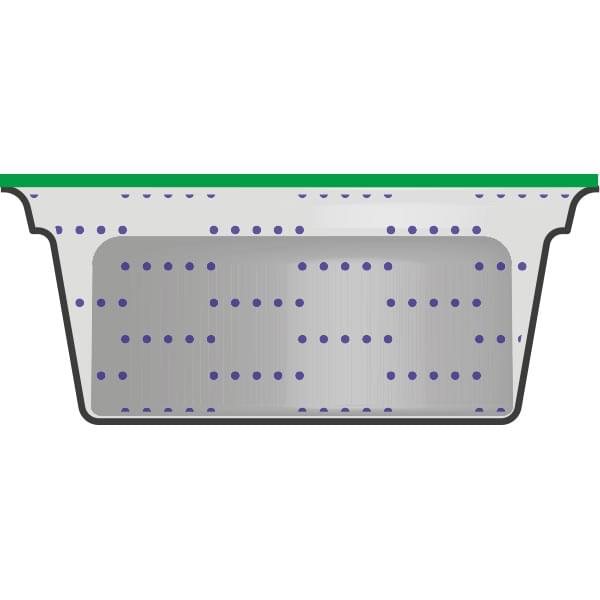

Technology

- PROGAS System

Technology patented by ILPRA that guarantees lower gas use and higher working speed. Available on all models of this series.

Product Gallery